It is a fact of life that we rely on adhesives far more than we might realise. To most people, ‘glue’ is simply the thing that we resort to when we have dropped a treasured family heirloom or need to reattach something that has unaccountably ‘come off in your hand’.

Invariably we grab a tube of glue from the kitchen drawer before hastily applying liberal amounts of it to the fractured item, in the vain hope that it will all turn out for the best.

In many cases, the procedure will end in failure, however, for a whole host of reasons. But why does that seem to happen so often? That’s where this guide comes in, where we take a look at the different types of glue.

However, first of all, a brief overview of adhesives in general won’t go amiss. As you will know from a visit to your local DIY store, there are hundreds of different products available.

The industrial sector has long since adopted adhesives in their many forms, both to speed up production and to cut down on material costs – added to which, in many instances, adhesives will actually outperform other, more traditional methods for attaching or joining things together.

An excellent example of this can be seen in what is currently the world’s most advanced passenger aircraft, the Boeing 787 Dreamliner, which uses adhesives extensively in constructing many of its important flight control elements, including such things as flaps and wing sections.

Needless to say, the adhesives in question in this case are very advanced indeed, and highly bespoke for the task that they have to perform.

For those of us back on terra firma, using adhesives can also be successful, just like knowing how to solder can be, so long as a few basic factors are taken into consideration beforehand.

There are, as mentioned, numerous types of adhesive, but the following are the main groups of interest to the DIY motorhome owner.

If you’re after a useful DIY project too, don’t miss our guide where we explain how to upgrade a TV amplifier.

Drying adhesives

These products have their adhesive element suspended in a solvent, so when they are applied, the solvent evaporates, leaving the adhesive element to harden and form a bond. They are probably the most common, versatile type of adhesive on the market.

Contact adhesives

These adhesives, which are solvent based, are usually applied to both of the surfaces to be bonded and then left to stand for a brief period of time, allowing them to partially dry before being pressed together.

Instant/Superglues (cyanoacrylates)

These are moisture-curing adhesives, which react with the moisture that is present on the surface of the items which are being stuck together, or with the moisture in the air.

Solvent adhesives

These adhesives function by dissolving the surfaces of the items being joined, before fusing them together. The solvent evaporates, leaving a ‘welded’ joint.

Heat adhesives

These products rely on a melted plastic acetate, applied with a heat-gun. This device melts a rod of the adhesive, which is then ejected from a nozzle onto the parts to be stuck together.

The melted plastic acetate adheres to the parts that are being joined, before cooling down and in the process, forming the bond.

Epoxy adhesives

Also known as two-part adhesives, these rely on the chemical reaction between two components.

Once they have been mixed together, the resulting compound cures and solidifies, forming the bond.

Points to consider when choosing the right types of glue

Choosing the right adhesive for the specific job in hand is paramount.

The materials to be bonded, the stresses to be encountered, and the environment in which the completed joint is expected to function – these are just some of the points that need to be considered:

Which materials are to be bonded?

Some adhesives remain flexible once they have set, whereas others will become rigid and unyielding.

What stresses will the bond be exposed to?

Different types of adhesive will have different load-handling properties.

Area to be covered

Some adhesives are more suited to sticking together large areas, such as bonding fabrics or attaching sheets of plywood.

Type of joint

Is it close fitting, such as you would find in a piece of broken china, or will there be the need to rely on the adhesive to fill in gaps where some of the material is missing?

Take a look at our guide to the DIY motorhome health checks you can carry out too, if you’re after some inspiration for tasks you can carry out to keep your ‘van in tip-top condition.

Choosing the glue

This is a selection of commercially available adhesives, covering the range of products discussed opposite, with a brief outline of their various uses, strengths and weaknesses

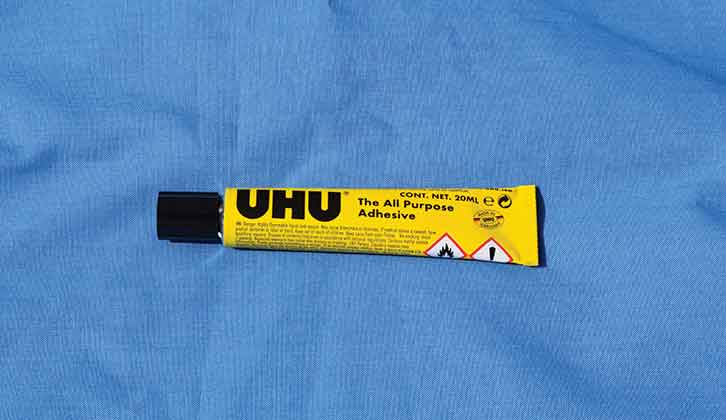

1. Nitrocellulose adhesive (clear glue)

This is probably the most prolific of the adhesives available. It is very versatile and can be used to bond many different materials.

It is a ‘drying’ adhesive; that is, once applied, it relies on its inherent solvent to dissipate, and then it will harden and form the bond.

It is moderately strong, but not flexible, and will adhere to most surfaces. Usually in tube form, it is easy to apply.

2. Contact adhesive

This type of glue will also have many uses. It is once again a ‘drying’ adhesive, in that it is solvent based.

Usually, both surfaces to be stuck together are coated with adhesive before being left to dry for a while.

Once a certain level of ‘tackiness’ has been reached, both of the parts are pressed together to form the bond. Full strength is normally achieved after a few hours.

This type of adhesive is particularly good if a degree of flexibility in the joint is required, because the product retains a ‘rubbery’ texture once set. It is also effective at handling any sheer forces that the joint might encounter. It is highly suitable for attaching such materials as laminates.

3. Instant/Superglue

Originally developed for use in clinical procedures (sealing and closing wounds), this adhesive has become a firm favourite.

As its name suggests, it has the property to ‘instantly’ attach the parts being bonded, with little drying time needed.

This type of adhesive has certain limitations, however. It works best when the parts to be joined are close fitting; if there is the slightest gap in the join to be filled, this product might not work.

In addition, this type is not the strongest of adhesives. It also has the drawback of ‘instantly’ attaching a careless user to anything they happen to come into contact with!

4. Epoxy (two-part) adhesive

These adhesives occupy a unique position in the range.

As their name suggests, they are supplied as two individual chemical compounds, which are mixed together, usually in equal parts, to form a paste-like third substance.

This is applied to the joint, where the chemical reaction continues until the compound forms a hard bond between the surfaces being stuck together.

This adhesive is very strong and can withstand a wide range of contaminants, such as oil and the like. It will also be capable of withstanding moderately high temperatures, although it will fail if subjected to temperatures above 150°C.

Epoxy adhesive is available in fast-setting (five minutes) and slow-setting (several hours) formats, making this a very versatile product.

5. Solvent adhesive

Usually used with PVC, this ‘welds’ the two parts to be joined together by melting them before the solvent evaporates, leaving the two surfaces joined. Acrylics are another material that can be bonded using appropriate solvent adhesives.

6. PVA (polyvinyl acetate) adhesive and sealer

Probably the most widely used industrial adhesive, this forms the basis of such things as wood glue and adhesive for sealing and adhering plaster to walls, and so on.

PVA is cheap (five litres can be purchased for as little as £12) and adheres readily to solid and woven materials.

It is also a ‘drying’ adhesive, setting once the solvent has evaporated away. Another advantage of this product is that it can be thinned with water until a good working consistency is achieved for the job in hand.

Any excess is also easily removed with a damp cloth while it is still wet.

Another point to bear in mind is that although PVA sets hard, it will retain some degree of flexibility when it is being used to stick cloth and the like.

The low price makes this adhesive very cost-effective for use in large areas.

7. Heat/Glue gun adhesive

This involves the use of an electrically heated ‘gun’, into which a plastic rod is fed. The rod is melted inside the gun and the molten plastic is then pumped through the nozzle onto the parts to be joined together.

It can be used on a wide range of materials and is good where small gaps are to be filled. This type of glue is highly versatile and used extensively in the furniture business and other sectors where a rapid and durable jointing method is called for.

Take a look at our guide to the essential items for every motorhome tool kit too.

After some more DIY ideas and inspiration? Then take a look at these…

- Diamond Dave explains how minor adjustments can make a huge difference to a motorhome.

- We shine the spotlight on window care and spotlight care.

- We talk you through the process of how to install QC 3.0 USB fast chargers and an 8-way fuse panel.

If you’ve enjoyed reading this article, why not get the latest news, reviews and features delivered direct to your door or inbox every month. Take advantage of our brilliant Practical Motorhome magazine SUBSCRIBERS’ OFFER and SIGN UP TO OUR NEWSLETTER for regular weekly updates on all things motorhome related.