These days, we all own multiple devices and gadgets, such as mobile phones, tablets and the like – most of which are pretty power hungry and require regular charging

to keep us connected.

When this is carried out at home, it is usually achieved via a charger plugged into a mains socket on the wall. However, when you are in your motorhome (especially if it is an older model), the periodic charging of these devices is often not nearly so convenient.

If you are not on a hook-up, for example, there is the lack of mains power supply to be considered.

In addition, when USB charging points are supplied, they are most probably of the standard fixed 5V 2A variety, which although adequate, will not provide optimum charging.

Rapid charging

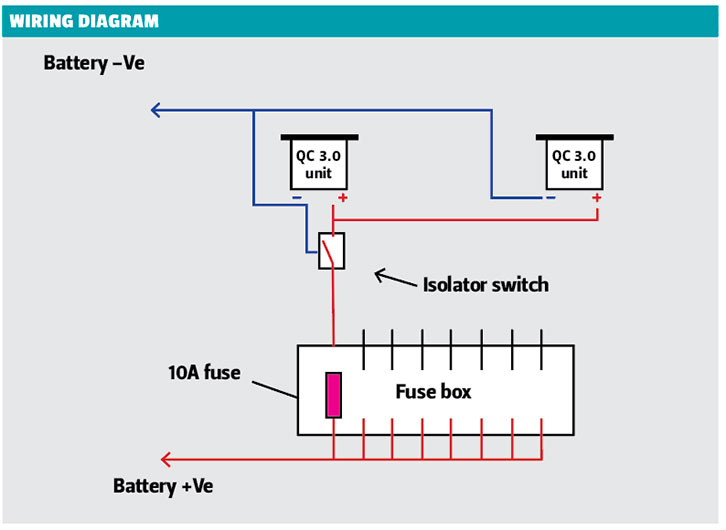

This article explains how to install a set of four QC 3.0 fast-charge USB outlets.

The USBs are connected to your motorhome’s leisure battery and are capable of safely and rapidly charging QC 3.0 compatible devices.

Non-compatible devices can also be charged, but not at the fast rate.

An additional feature of these outlets is an LED battery condition indicator, which gives a useful voltage reading for the leisure battery.

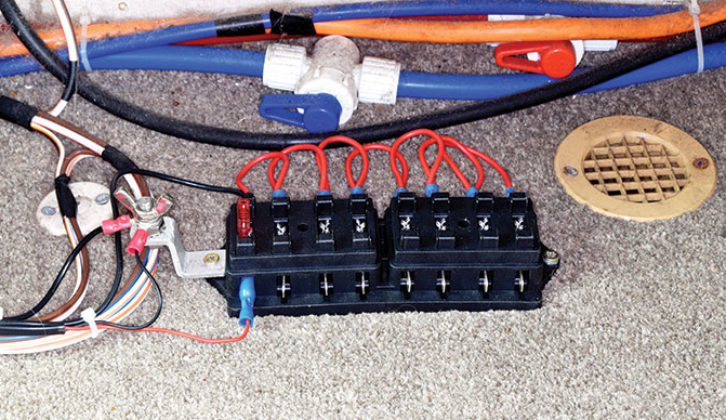

Fuse panel

QC 3.0 Usb fast chargers require fuse protection, so I have also outlined the installation of an eight-way blade fuse (normal car-type fuse) carrier.

Although only one position will be needed with a 10A fuse for the supply to the QC 3.0 chargers, the other seven spots will be available for any subsequent 12V gizmos that might require a fused supply from the leisure battery at some later date.

Naturally, if only the QC 3.0 chargers are being installed, a single in-line blade fuse holder can be used.

What is QC 3.0?

Developed by US wireless tech specialists Qualcomm, QC 3.0 is an intelligent battery-charging protocol, allowing compatible devices to be charged using higher voltages and currents.

Device and charger interact to control charging conditions and any possible overheating that might occur.

Devices must be compatible with the fast charger (details for individual devices can be found online) and a fast-charge high-current interfacing USB cable must also be used.

On average, compatible devices can be fully charged in a fraction of the time taken by older systems.

Safety notes

1. Any fuses must be fitted in the 12V +Ve wire adjacent to where it leaves the battery. This minimises the risk of fire in the event of a short circuit happening anywhere along the charger’s feed wire.

2. The battery’s –Ve terminal should be safely disconnected while making the connections to it, because any inadvertent short circuit of an unfused supply will result in high currents and possible fire.

Tools required

- Crimp tool (about £10 on eBay)

- Standard toolkit (wirecutters, strippers, screwdrivers and so on)

- Hole cutters

- Power drill

- 4mm drill

Parts list

- 1 x 12/24V eight-way heavy-duty fuse box (compatible with standard car blade fuses), £9

- 1 x 10A 6.3mm blade fuse

- 2 x QC 3.0 dual USB fast charger socket power outlets with LED voltmeter, £8 each

- 1 x round 12V/20A rocker switch with LED indicator

- 1 x M6 x 16 screw

- 1 x M6 nut

- 2 x M6 washers

- 1 x M6 locking star washer

- 1 x M6 wing nut

- 13 x 6.3mm crimp spade connectors (for charger and fuse box connections)

- 3 x 4.8mm crimp spade connectors (for rocker switch)

- 2 x 6mm crimp eyelets (for battery and charger earth returns)

- Length of 11A flat twin thin-wall cable, to suit installation being undertaken

- Cable clamps. I used self-adhesive ones, although the type used will depend on the installation being undertaken

Skills required

The ability to carry out rudimentary wiring and basic carpentry (hole cutting in panels)

Note: QC 3.0 charger units can be fitted on any flat surface capable of accommodating required wiring connections behind them

Step-by-step guide to making QC 3.0 Usb fast chargers

1. One of the two QC 3.0 USB fast chargers fitted to a windowsill.

2. QC 3.0 USB charger unit before installation on the windowsill.

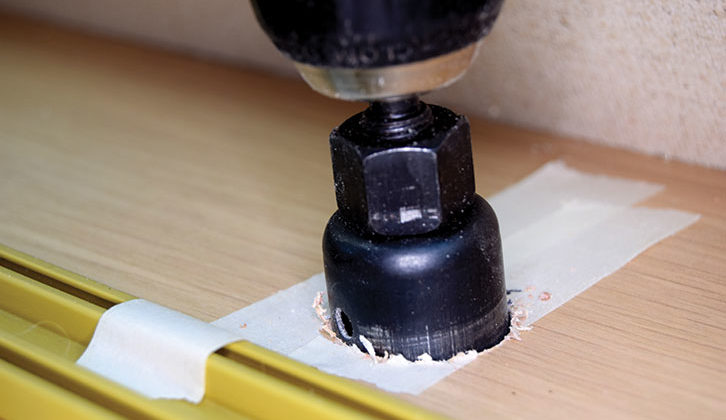

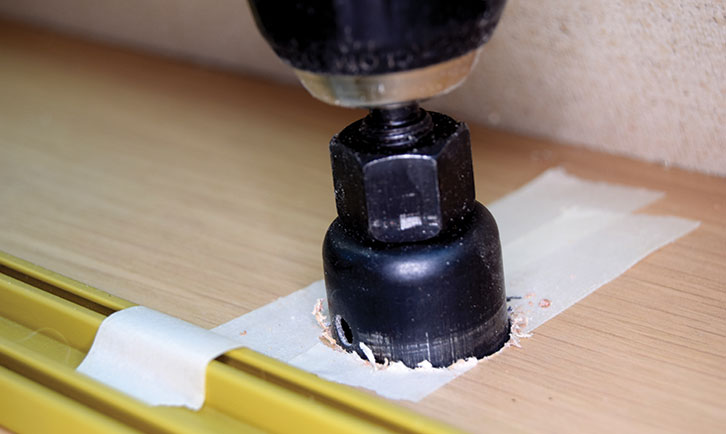

3. Mark location points on masking tape, then drill 4mm pilot hole.

4. Use 28mm hole cutter to cut a hole for each of the chargers.

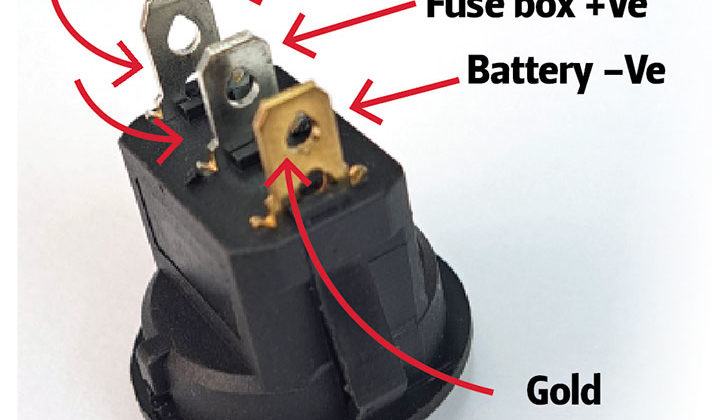

5. By charger fed from fuse box, cut a 21mm hole for isolator switch.

6. Earth post of scrap aluminium; dimensions are not critical.

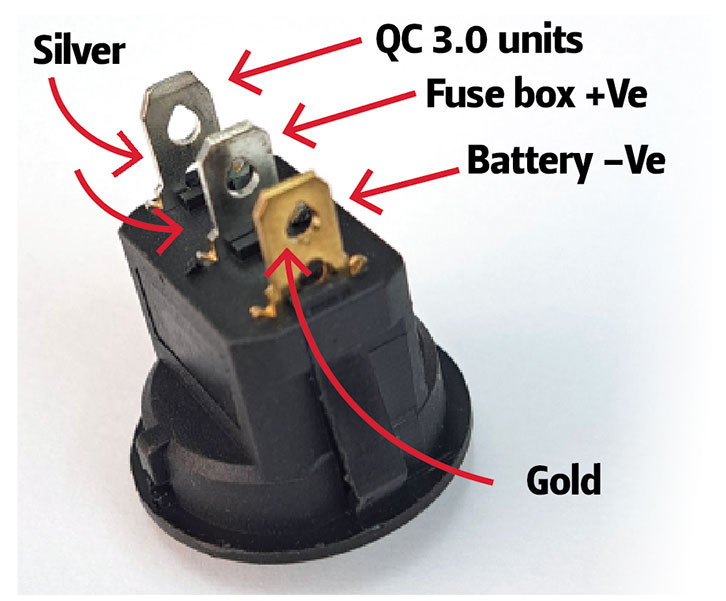

7. Rear of isolating rocker switch showing connection details.

8. Charger installed, with the LED display showing battery status.

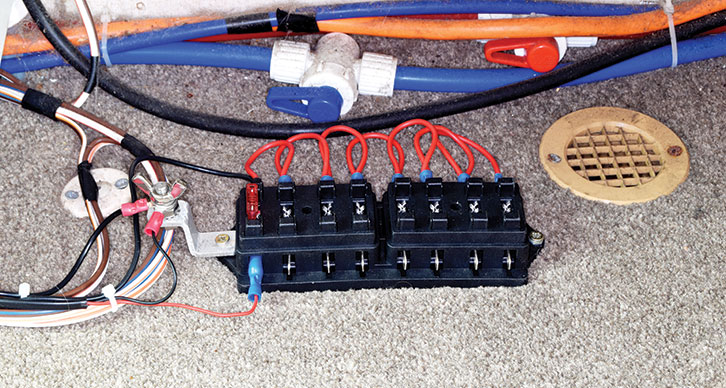

10. Fuse box with earth post secured by fixing screw to the floor.

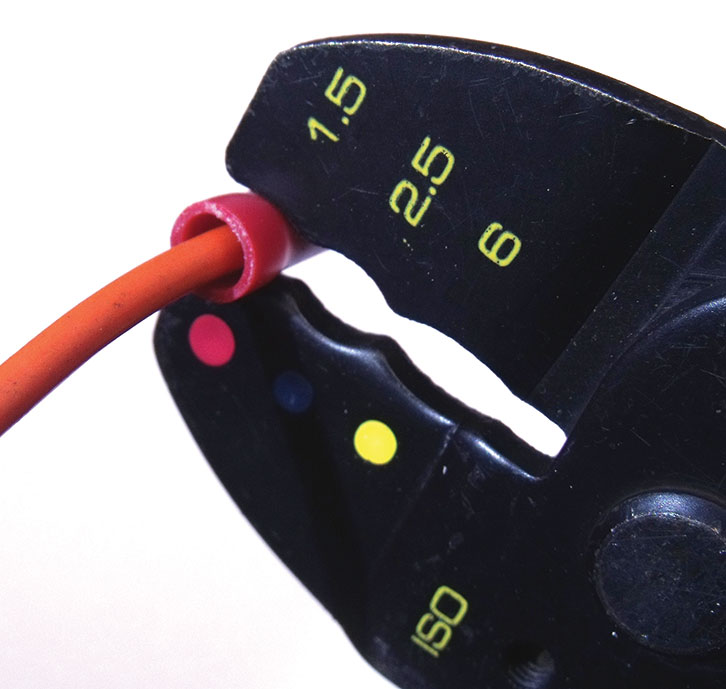

11. Securing the crimp connectors using the crimp tool.

Future Publishing Limited, the publisher of Practical Motorhome, provides the information in this article in good faith and makes no representation as to its completeness or accuracy. Individuals carrying out the instructions do so at their own risk and must exercise their independent judgement in determining the appropriateness of the advice to their circumstances. Individuals should take appropriate safety precautions and be aware of the risk of electrocution when dealing with electrical products. To the fullest extent permitted by law, neither Future nor its employees or agents shall have any liability in connection with the use of this information. Double check any warranty is not affected before proceeding.

After more tutorials? Then how about these:

- We talk you through how to care and repair your motorhome’s rubber seals

- Sam Coles explains how you can make your own versatile drinks stand

- Nigel Hutson tells you how to clean your Omnivent

If you’ve enjoyed reading this article, why not get the latest news, reviews and features delivered direct to your door or inbox every month. Take advantage of our brilliant Practical Motorhome magazine SUBSCRIBERS’ OFFER and SIGN UP TO OUR NEWSLETTER for regular weekly updates on all things caravan related.