I’m often surprised that when people are buying a motorhome some of them seem to pay little – or no – attention to the way their vehicle’s body is built.

At least four elements are influenced by a motorhome’s body construction: repair procedures, strength, weather resistance and weight. Not surprisingly, there are contrasting types of assembly and the workmanship needs to be checked. Elsewhere we look at motorhome chassis construction and at the improvements made following motorhome safety testing, but in this article we’re looking at the features of a campervan’s exterior.

Van conversions

The steel shell of a light commercial van will have been thoroughly tested before a converter commences fitting it out. Sometimes this procedure entails the installation of an elevating or high-top roof. Occasionally, a rogue fitter will fail to implement crucial restrengthening strategies.

For instance, when a roof panel is removed, the entire shell can be weakened if compensatory steel members specified by a vehicle’s manufacturer are omitted.

Let’s be clear about this: the mere addition of a replacement GRP (glassfibre) roof moulding does not provide the strength that an altered structure is likely to need. There was even a recent case in which a retrofitted roof installation failed and the van’s high-top moulding was in danger of becoming detached while in transit on a motorway.

Apart from such a worrying scenario, accident repairs and routine cleaning operations on panel-van conversions follow normal vehicle procedures. Equally there shouldn’t be any leaks in a converted panel van – as long as components such as windows and ventilators have been installed and sealed correctly.

Bonded panels

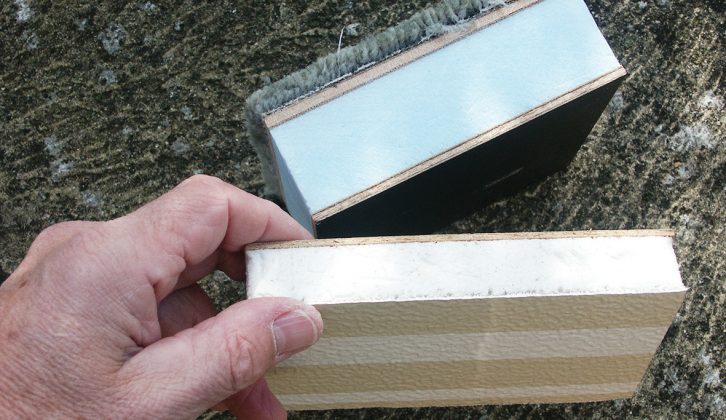

It’s around 35 years since caravan and motorhome manufacturers started to use prefabricated floor and wall panels. These composite products employ what is known as ‘sandwich’ construction and it’s interesting that none of their three components have individual rigidity. Only when the sections are bonded together is there a rigid panel that includes thermal insulation and is light in weight.

Originally its external skin consisted of painted aluminium sheets; today this material is still used. However an increasing number of panels are being finished with flat panels of glass-reinforced plastic (GRP), which is also known by some as glassfibre.

If an aluminium skin is badly damaged, the usual strategy is to bond a new sheet on top of the old one. That’s neither a quick nor easy operation; delivery delays can compound the trouble involved.

In contrast, a damaged GRP panel can sometimes be repaired in situ by an experienced laminating specialist. Nevertheless, a small dent in either type of facing material can occasionally be hidden with a ‘patch repair’ and matching paint.

One criticism when prefabricated boards are used to form a living enclosure is the fact that it looks very boxy. On the other hand, it’s easy to mount furniture against flat, vertical walls.

Coachbuilt GRP shells

In the 1980s, Auto-Sleepers commissioned William Towns, a notable car designer, to create a GRP monocoque (one-piece) enclosure for a new range of coachbuilt motorhomes. His previous work included the Aston Martin Lagonda launched in 1976 and many versions of his motorhome design were built for Auto-Sleepers by a Cheltenham GRP specialist in the years that followed.

Other shapely GRP ’vans have been created, including Barry Stimson’s Odyssey, which won a Best Motorhome Award in 1998. Other examples of his previous GRP designs include the much-loved Romahome.

Other GRP structures have been used on models from Esterel and Mobilvetta. This building material permits the creation of vehicles with curved lines and the Italian-made Wingamm ’vans prove the point. In addition, damaged GRP bodywork is easy to repair, but the task of installing insulation and a lining ply inside is a time-consuming job. I learned that the hard way when fitting out my own monocoque motorhome. The final results can also be heavy, although a shell without any joins is great whatever the weather.

Prefab-panel hybrids

Although Auto-Sleepers’ monocoque GRP models were justifiably popular, the company later embraced the two building strategies we’ve already described.

When the Auto-Sleeper Pescara and Pollensa models were developed, these medium-sized coachbuilts used some GRP mouldings but matched them with flat sandwich panels for the side walls. The resulting vehicles still had attractive shapes but it was easier to install furniture inside. Other manufacturers also adopted this hybrid approach.

The strategy undoubtedly speeds-up the construction but it has to be recognised that when a bodyshell uses several dissimilar products, they often have different rates of expansion. Accordingly, if adjoining panels are subjected to strong sunshine, their rates of expansion may differ. In some instances, that can cause gaps to appear.

In order to preserve a structure’s resistance to rain, junctions between dissimilar panels have to be sealed with a flexible, non-setting mastic. This achieves weather resistance – until the mastic eventually dries out and goes brittle. Rainwater ingress then becomes a threat and that’s why routine checks with a damp meter can signal when attention is urgently needed.

Another issue arose when instead of using GRP body components, manufacturers started to use mouldings made of ABS plastic. This is easy to spot because, unlike GRP, this material is shiny on both faces.

Typically, motorhome ABS components are also thin and if subjected to a strong bump, they’re likely to split or break into pieces. Perhaps that isn’t too serious for a small housing which accommodates a rear road light but ABS mouldings are sometimes used to form the entire rear wall of a ’van.

In reality, this material is often repaired using techniques similar to those used to repair a GRP panel, although the chemicals employed are quite different. What’s more, repairers seldom undertake ABS repairs, preferring to replace panels completely. That’s worrying when large ABS mouldings can cost four-figure sums and their delivery can take weeks, disrupting holiday plans.

Unfortunately few motorhome purchasers check whether items like plastic underskirts or other body-trim mouldings are made in ABS or GRP, which has implications if you have a small bump.

Lastly be aware that the long-standing practice of screwing wall panels to roof sections can sometimes introduce potential leak points. This led Bailey of Bristol to employ a clamping system that is often used on large box trailers – such as roadside tea bars – and the company adapted the components for use with caravans and motorhomes. Known as Alu-Tech, the system was used on Bailey’s Pegasus caravan launched in 2009 and used when it started manufacturing motorhomes. The photographs show how the components are assembled.

Points to check before you buy

Both good and bad points can be seen in motorhomes. Check out our guide to buying a used motorhome, and browse through our final six photographs above as examples of things to check before purchase. This may mean you even need to inspect the roof; it is always disappointing when elements that are normally out of sight are poorly finished.

If an aluminium skin is badly damaged, the usual strategy is to bond a new sheet on top of the old one