Motorhomes come with a whole variety of external doors and lockers (garage, gas, toilet cassette and so on). Inevitably, they have some form of catch to keep them open while you are rummaging about inside.

In most instances, these catches use friction as the retaining medium. Some are assisted by springs (nylon or metal), but still have a friction action as the mainstay of their operation.

I have an assortment of door catches spread around the outside of my ‘van and they all have one thing in common – they’re not particularly brilliant to start with and their operation deteriorates over time, owing to frequent usage and exposure to the elements.

This project shows you how to make a magnetic catch, thus removing the reliance on friction.

Magnetic external catches are readily available on the market. However, they can cost anywhere between £25 and £30 for each pair, whereas the catch in this project costs in the region of £6.50 per pair. Not only is my catch cheaper by a stretch, but the magnets used are the rare-earth neodymium type (often referred to as ‘super magnets’) and are very powerful (see below), ensuring a firm holding force when the door or locker is open. These are the very magnets that have made the likes of drones and electric bicycles possible!

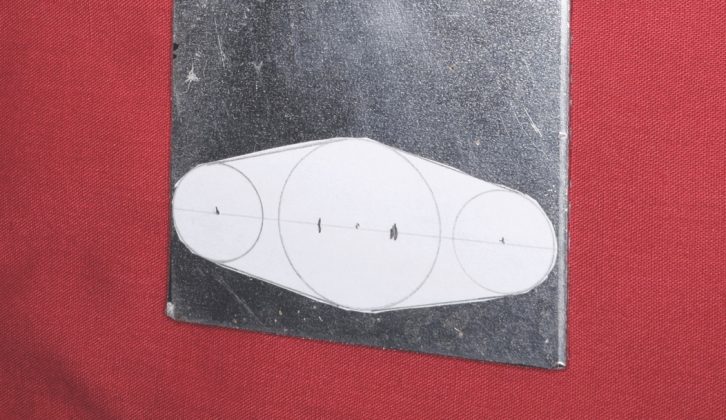

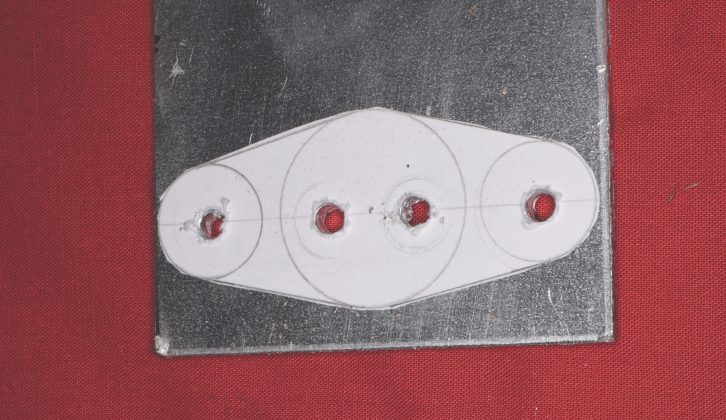

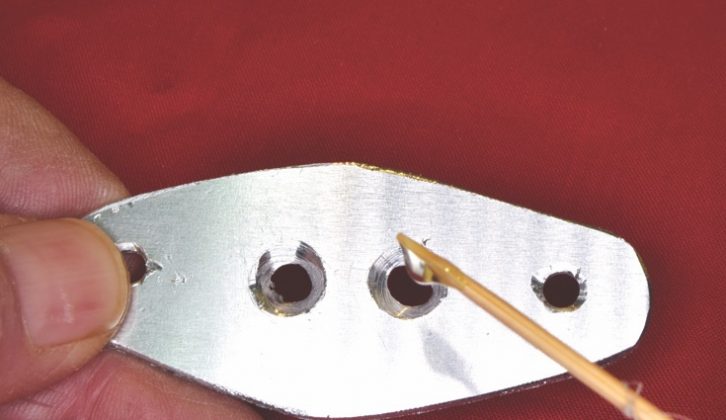

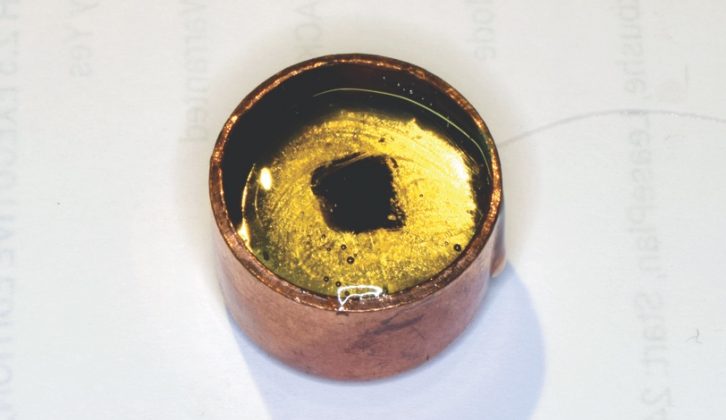

You can find a list of parts and tools required to complete the project below, with a step-by-step photographic guide above.

Warning note

Neodymium magnets are extremely powerful, and will attach to each other with great force if they are placed in close proximity to each other.

As such, they should be treated with considerable respect, because it is very easy to get skin, fingers or clothing trapped between them.

For this reason, they should never be given to children as a toy.

When working with magnets, metal tools should also be kept at a distance, otherwise they will forcefully attach themselves to the magnets, possibly causing injury and damage.

Another concern with these magnets is that they are brittle and will shatter if allowed to drop onto a hard surface or to slam into each other. They will also rust if exposed to water – in this project, they are sealed in epoxy, so the aforementioned problems don’t arise.

For the catch assembly, non-ferrous materials (copper and aluminium) have been used. This means that the various parts will not be trying to grab hold of the magnets during the assembly procedure, which could make for a potentially very difficult situation.

Parts

- Neodymium magnets, 20mm diameter x 10mm deep. These should be readily available, for example on eBay. For my project, I bought some at a cost of £8.50 for five, with free postage and packing.

- Copper 22mm end-caps. These can be bought in any DIY store.

- Epoxy resin. A dual pack 25ml dispenser will be ample for making several catches.

- Aluminium plate 3mm thick. Once again, eBay has many suppliers.

- M4 x 6mm stainless steel countersunk screws.

- Nitrile rubber sheet. Many suppliers can be found on eBay.

Tools

- Conventional toolbox

- Drills

- Hacksaw

- 22mm washer punch (although scissors will suffice)

Not only is my catch cheaper by a stretch, but the magnets are 'super magnets' that are very powerful, ensuring a firm holding force when the door or locker is open