Crockery is often kept in a top cupboard in the kitchen, where ‘van manufacturers provide plastic-covered wire racks for this purpose.

Unfortunately, plate racks are often fitted in cupboards facing the direction of travel, with doors that have non-positive catches. In the event of an emergency stop, the plates might land on the floor in a heap of fragments, and even if not placed in this direction, wire racks usually waste a great deal of space.

In our motorhome, I did think the original wire cupholders looked promising. But when I reached my destination, the top cup had been jumping up and down on the one stored below, with quite disastrous results.

A much better system would be to remove any shelves from your cupboard, preferably side-facing, and fit your own shelves, to suit the dimensions of your plates and cups.

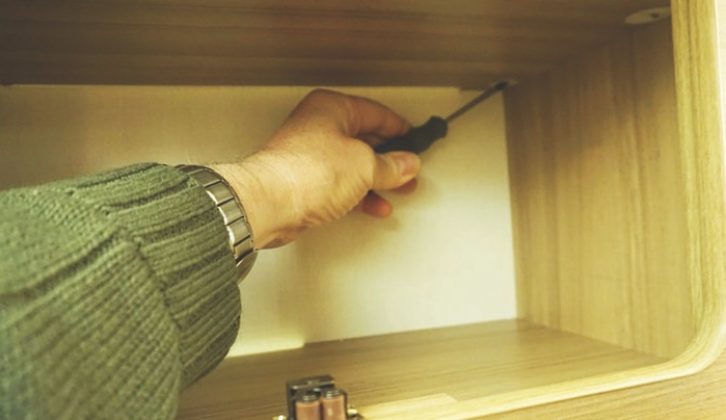

A weight-saving solution would be to fit wooden shelf support strips to the side of the cupboard, but to complete this project without drilling any holes in the ‘van – so it is totally reversible – I made some templates for the cupboard sides and cut plywood sides to a loose fit. This has the added advantage of allowing you to glue the shelf support strips on the bench, before putting the sides in place. The only thing that retains these pieces is the shelves themselves, which keep them pushed to the sides.

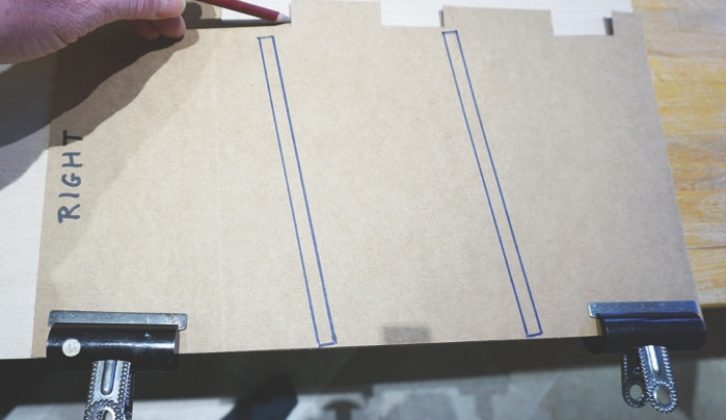

Making templates

Stiff paper is ideal for making the side templates, which can easily be cut to fit around any corner fittings or wiring, and marked with the shelf supports, which are better when they are angled down towards the back of the cupboard.

Next, transfer these to some plywood. I used 9mm hardwood ply, which takes a better finish when varnished than that of conventional softwood ply.

Some weight could be saved by using thinner ply, but our much-loved Corelle tableware, although thin and stacking-compact, is quite heavy and will become, in effect, heavier when we go over a bump.

Cut out the plywood sides, then mark them up together, back to back, so that all of the measurements for the shelf supports are matching.

Just a quick tip. When glueing on the shelf supports with PVA adhesive, or in fact, glueing any two pieces, knock a couple of tiny panel pins partly into one side of the proposed glue joint, then cut them off with wire cutters. This will leave a small prong protruding, which can prevent side-slip when the joint is clamped up.

Temporarily fit the sides, then measure and cut the shelves. If these are planned as an easy fit, they can be tightened later by using some thin packing on the back of the side pieces. Now you just need to sand and add a couple of coats of varnish, and the main woodwork is complete.

By upholstering your shelves with vinyl over carpet underfelt foam, you can take out some of the bounce experienced when going over bumps with the motorhome, but it is best to fix your hardwood angle or aluminium angle edge trim with screws after upholstery is complete, so the vinyl can be replaced later if necessary.

In an emergency stop, unsecured plates might end up on the floor