In part four of our series, Peanuts’ roof receives some vital repairs, and Gentleman Jack offers advice for the less experienced DIYer

[tl:gallery index=1 size=215×129]We’re doing some roof repairs this month – the Auto-Sleeper elevating roof was in need of some TLC. Fortunately, it’s an easy apparatus to work on, because the sides hinge inwards (see picture 1, below). Well, more accurately, they should do – see picture 2. This photo looks over the top of the wardrobe and shows the damage caused by seized hinges. Some B-B (bird-brain) had replaced the originals with cheap steel [tl:gallery index=2 size=215×129]ones without any hinge-pin spacers and the inevitable happened: they rusted solid, causing the lower beading to bulge (visible above the paint dribble) and the upper beading to pull away from the roof side panel.

The first job was to gently prise [tl:gallery index=3 size=215×129]off the wooden beading and remove the old hinges. I say ‘gently’, because we aim to reuse as much material as possible to keep costs low. Next we removed the old fabric draughtproofing. Replacement brass hinges (which don’t rust) were attached in new locations (see pic 3) and new plasticised linen draughtproofing applied – we used a specialist Duck adhesive tape (I always keep a roll in the workshop) for the job.

Finally the old beading was [tl:gallery index=4 size=215×129]reattached with new panel pins (pic 4). The interior will be refinished, but not until we’ve got everything working perfectly.

Top tip: always lubricate hinges after installation and at regular intervals. I never use oil or WD40 inside a motorcaravan – the smell is awful! I always use a quality aerosol furniture polish with added beeswax. It’s a brilliant lubricant, it doesn’t run everywhere and smells lovely.

The nearside hinged panel had a [tl:gallery index=5 size=215×129]different problem (pics 5 and 6). These panels tend to bow slightly over time, but ‘B-B’ had been at it again here. This time, he had repaired the hardwood, reinforcing it from the wrong face and with nails. A major split was the result. Exterior wood glue, G-clamps and brass screws effected a repair (pic 6). No money required, just [tl:gallery index=6 size=215×129]a bit of patience.

Top tip: Use plenty of glue. If it doesn’t squeeze out as the clamps are tightened, you haven’t used enough. Remove surplus with a damp cloth. If you haven’t any clamps, get some – they’re useful for all sorts of jobs.

Picture 7 shows a section of the [tl:gallery index=7 size=215×129]piano hinge between the roof lid and back panel, and the hinge is beginning to fail. Part of the hinge-pin has seized, broken or just fallen out. It’s not a difficult job to replace the piano hinge, but it’s an odd size and I couldn’t get hold of a replacement in time for this month’s column.

Finally, replacement rubber seals [tl:gallery index=8 size=215×129]were sourced and stuck on with contact adhesive. Apply the adhesive to both surfaces, wait until they’re touch-dry and press together.

Top tip Never apply contact adhesive from the tin – you’ll get it all around the threads for the cap. Put some into an old jar and use a cheap, disposable paint brush to apply it.

OVERDRIVE UPDATE

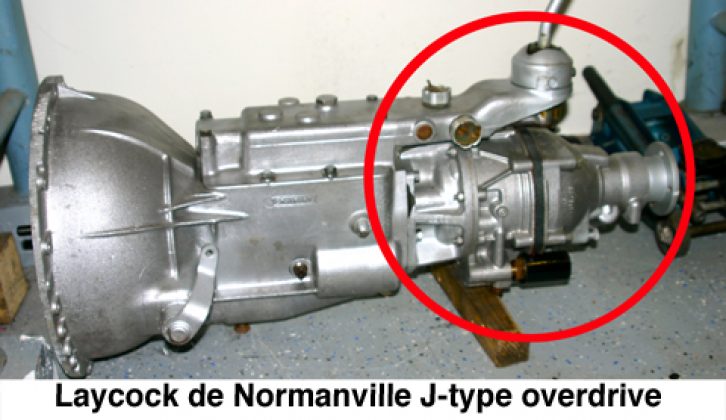

First, I’d better explain for the benefit of younger readers that Peanuts’ after-fit overdrive unit is really another gearbox bolted on to the back of the standard four-speed [tl:gallery index=9 size=215×129]one. In effect, it gives a higher ratio, equivalent to fifth or sixth (top) gears in modern vehicles.

The overdrive is operating well now after last month’s foolish wire-waggling incident. I wasted about four hours trying to repair the connection to the old actuating solenoid, before giving up and buying a complete new actuator unit from Overdrive Repair Services. They are the experts on Laycock de Normanville overdrives and even make complete new units which they fit to modern vehicles. What de Normanville quaintly referred to as a ‘low-speed sensor’ (actually a detent switch that should allow overdrive to operate only on third and fourth gears) wasn’t wired up – this explains why overdrive could be engaged in any gear. The inhibitor switch is to stop powerful engines damaging the overdrive’s planetary gears. Extensive torque and high revs are definitely not a feature of our ancient B-series petrol engine, and it has a ‘milk float’ back axle (very low final drive ratio), so I’ve decided to leave it without the inhibitor.

Fancy that! Although de Normanville sounds French (and it was originally), in this case it belonged to a British-born inventor called Captain Edgar J. de Normanville, who was also the technical editor of ‘Motor’ from 1908.

So far…

The roof is now 90 per cent repaired, so Peanuts has been pressed into use as weekend holiday accommodation ahead of schedule. I’ve banned anyone from using the gas system until I’ve had time to examine it closely. In the interim, Kate (the owner) is using a small camping stove that runs on disposable cartridges. Next week, it’s the MoT… gulp!

To do list

- Shake down DONE

- Urgent mechanical repairs DONE

- Mechanical safety check, lubrication service DONE

- Habitation safety check

- Repair elevating-roof, fit new rear-door cards DONE

- Refinish cabinetwork

- Upgrade soft furnishings

- Makeover for bodywork

- Upgrade safety equipment

- Upgrade power (both 230V and 12V systems)

Oops! That wasn’t supposed to happen!

I shut the rear door and was left [tl:gallery index=10 size=215×129]holding the handle and lock in my hand – B-B again! This time B-B had used a wood screw to hold the lock’s bar to the interior handle. By doing so, he had wrecked the thread inside the bar. I used a tap and die set to repair the thread. Then the wood screw could be replaced with a proper bolt.