Lithium batteries are gradually coming down in price as more and more names appear on the market. But what are they? Why are they so expensive? And what advantages do they offer?

What do we need to look out for when replacing a trusty lead-acid battery with a lithium alternative?

Lead vs lithium

Look at a conventional 100Ah lead-acid battery – it’s just a pile of chemicals, lead sulphuric acid and so on in a plastic box. To be precise, six boxes connected in a series (side by side), as each nominal 12V battery has six cells, each delivering a nominal 12V.

Lead-acid batteries have a finite life, and the advice from many quarters is not to discharge your battery below 50% of its rated capacity, to achieve a reasonable life. So in practical terms, your 100Ah battery should actually be considered a 50Ah battery.

And we mustn’t forget Peukert’s law, named after the German professor who noticed that the faster you discharge a lead-acid battery, the less Ah you will get out of it. Not good if you are operating greedy devices, such as a powerful inverter to run the microwave, for example. And if you have ever changed a lead-acid battery, you know they are heavy!

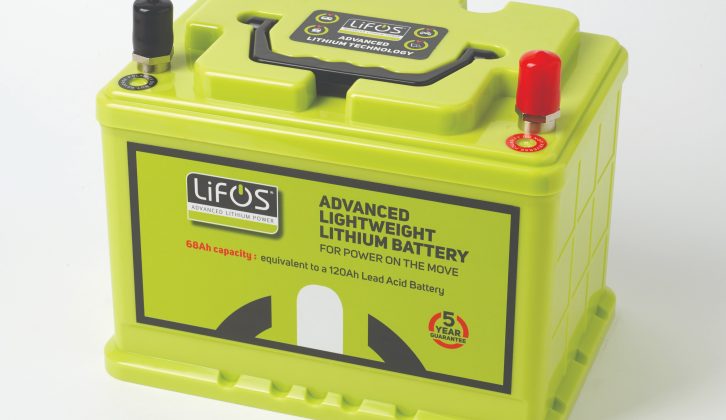

In terms of performance, lithium-iron-phosphate (LiFeP04) batteries beat lead-acid hands down, but at a price of around £10 per Ah.

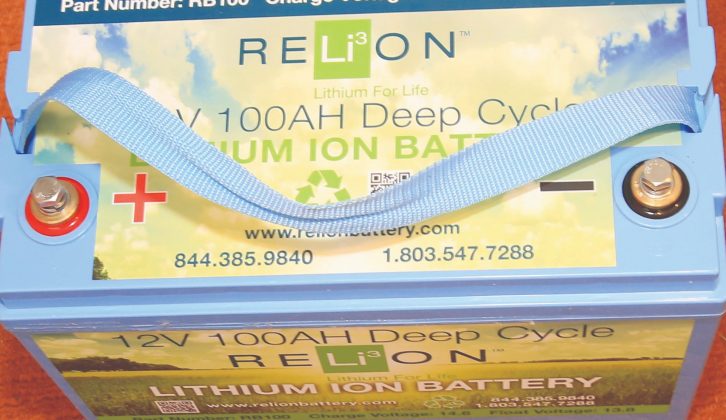

Lithium-iron batteries are not subject to Peukert’s law – what you put in, you get (almost all of) back out. Battery life is typically 10+ times that of lead-acid, and you can discharge the battery by 90% every time and still achieve this.

Weight saving

Lithium-iron batteries are also much lighter. One 150Ah battery will hold the same amount of useable ampere-hours as three 95Ah lead-acid batteries, but will save you more than 60kg of weight – that’s nearly a person!

So these are not just posh batteries for the upmarket liners, but a valuable tool for those of us struggling to stay within that 3500kg limit.

Just four cells

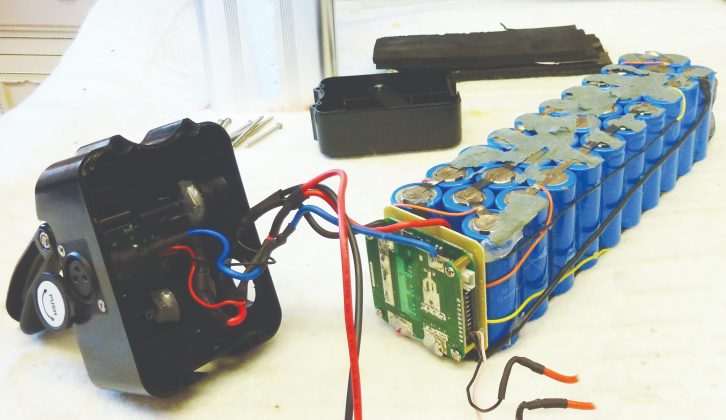

A nominal 12V lithium-iron battery comprises, in effect, only four cells connected in series.

Each of these cells is made up from many smaller cylindrical or prismatic cells, connected in parallel to make the four main series-connected cells.

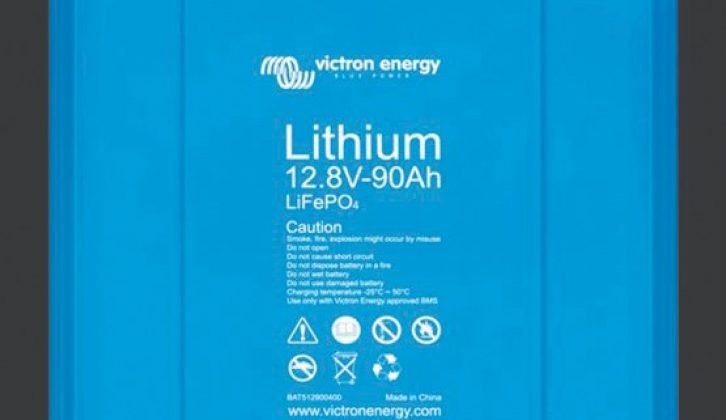

Although the lithium-iron battery construction is said to be intrinsically safe, it is very important that charge and discharge voltage limits are not exceeded on a cell-by-cell basis.

Battery management system

Within the battery case is the battery management system (BMS), which monitors the voltage of every cell and will switch off the battery if this exceeds set limits.

Lithium-iron batteries charge and discharge very rapidly, so are ideal for heavy loads such as that inverter-powered microwave. But both charge and discharge current are limited by the size of the BMS.

A battery with a 50A BMS will be no good to power the microwave, and a tad limiting if you wished to charge your battery very fast with a 100A battery-to-battery (B2B) charging unit when mobile. So checking this detail is important when choosing which battery will suit you best.

Temperature

Lithium-iron batteries provide power down to about minus 20C, but the minimum temperature for charging them is close to 0C. Force charge into it at sub-zero temperatures and you will cause permanent damage.

Some BMSs monitor temperature and stop the battery accepting a charge in such cases. Others have a heater, so the charger energy initially powers that until the cells are warm enough.

Advanced Battery System variants (from Hymer) have batteries with built-in heaters, and each 135Ah lithium battery is actually six smaller 12V batteries.

General advice is to mount the battery in the living area – under a seat, for example. Some converters now provide heated battery lockers.

Charging

Most suppliers advertise batteries as ‘drop-in replacements’, but caution is required. The ideal maximum charge voltage is 14.6V, some say plus or minus 0.2V. Ideally, once this voltage has been reached, charging should be switched off until you have taken 10% out of the battery. Others say to reduce the voltage to 13.8V maximum. All very close to many smart charging systems.

This means that your mains hook-up charger, the vehicle-powered charging system, and the solar panel and regulator all need considering.

Note that major manufacturers of these charging systems offer dedicated units for lithium-iron batteries.

Some lithium-iron batteries are offered with a plug-in display so you can monitor voltage, charge, or discharge amps and the percentage remaining. Others incorporate Bluetooth and can be monitored through your smartphone.

Warranty and certification

Warranties vary in length, although most are about five years. Even so, users are unlikely to get close to the cycle life of these batteries within the guarantee period.

Lithium-iron batteries must be CE compliant, so look for the CE mark.

Lithium-ion (not iron)

Lithium-ion, which is a different kind of battery, powers the many electric bikes you see about these days. The cell voltage does not work out well – to add up to a nominal 12V would require about 3.5 cells!

But they are assembled similarly, from lots of small cells, to make higher-voltage batteries for e-bikes, typically between 36V and 42V.

Many smartphones are powered by one such cell. These do not share the intrinsic safety of lithium-iron and have been known to catch fire when chargers fail. But they are supreme in power-to-weight ratio.

In terms of performance, lithium-iron-phosphate (LiFeP04) batteries beat lead-acid hands down