Mandatory items when you are travelling in mainland Europe include hi-vis jackets and a red triangle which, in the event of a breakdown, must be displayed at a distance from the rear of your ‘van to warn oncoming traffic of a stationary vehicle ahead.

Most of the commercially available triangles are of the folding variety, which come packed inside some sort of plastic sleeving for storage. But in the main, they are quite small and can easily be missed when deployed.

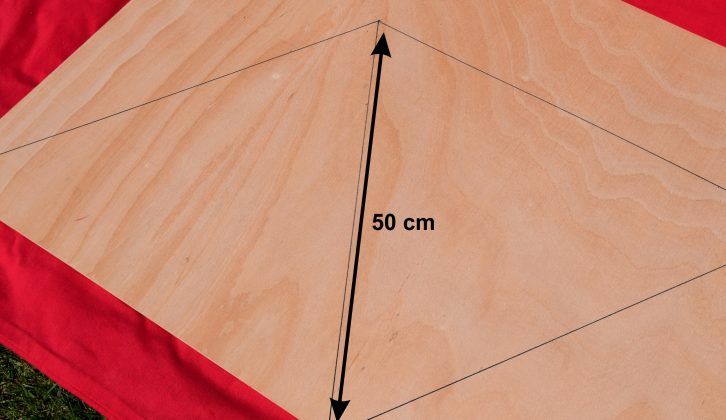

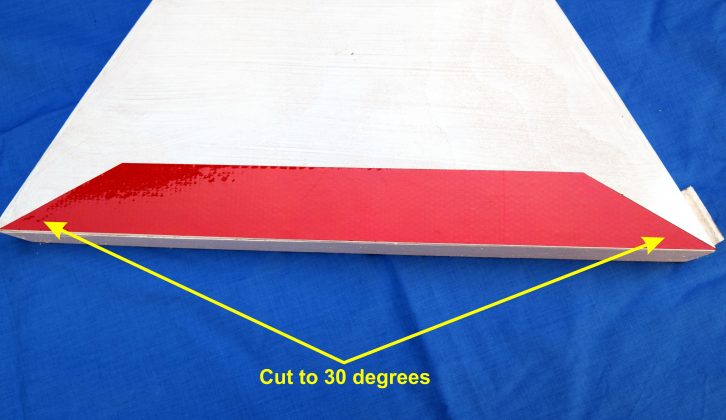

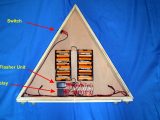

This project covers the construction of a 450mm high triangle that has a large reflective red and yellow surface area and alternately flashing red LED triangles (one inside the other), which draw attention to it, especially at night. (We would advise using it to supplement your original triangle, rather than replacing it.)

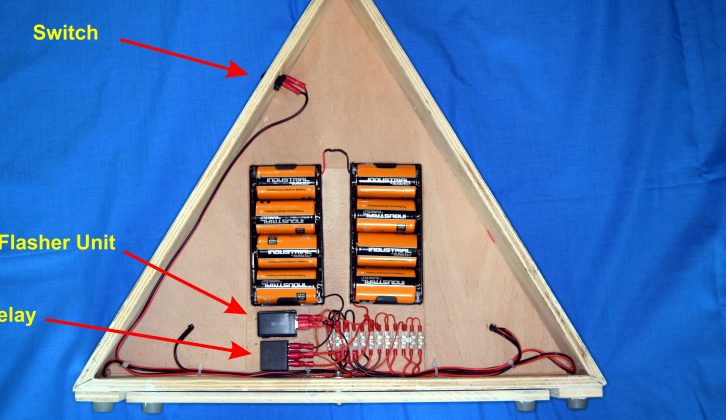

The two LED triangles are driven by an electronic car flasher unit, which in turn powers the operating coil of a changeover relay, also commonly used in cars. Although heftier than needed, both have been chosen because they are cheap and readily available.

The power source consists of eight alkaline D cells in series (the battery holders will need to be connected accordingly), giving 12V. D cells have a long storage life and the warning triangle will, it is to be hoped, spend long periods not being used. Should the need arise, they have plenty of capacity to run for extended periods.

Batteries should be replaced if the triangle is used for any period of time. Although most modern batteries are sealed and won’t leak if discharged, finding that the batteries are flat in an emergency is best avoided.

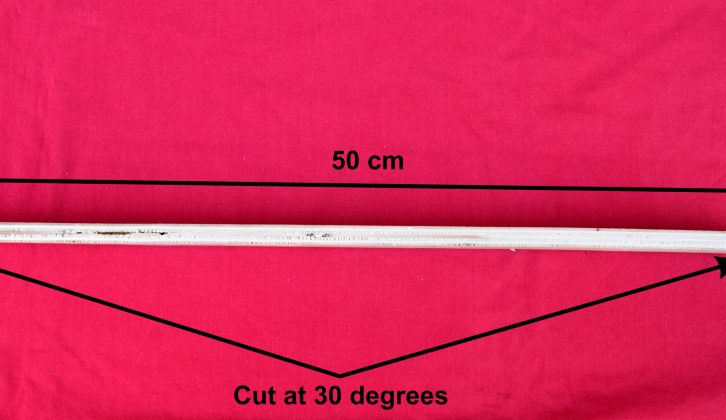

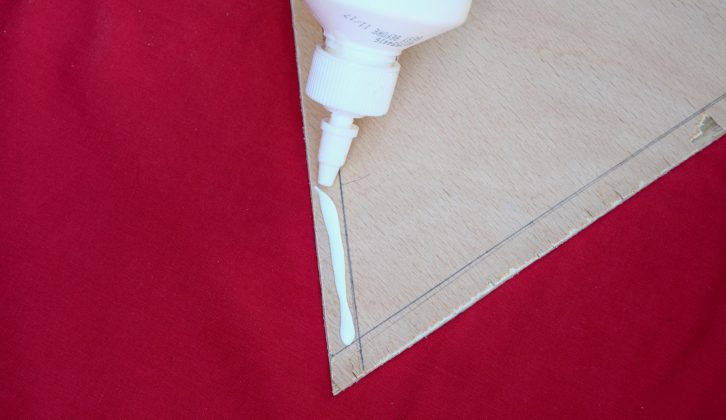

The skills needed to complete this project are an ability to solder and to carry out basic carpentry.

For full, step-by-step instructions, see the photos above.

Parts

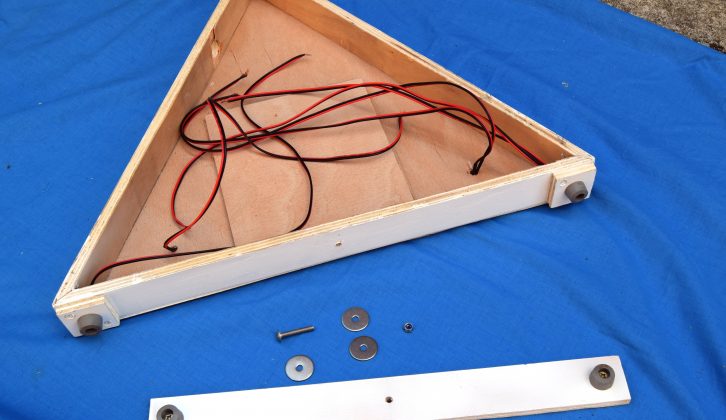

- Sheet of 36mm plywood (1220x600mm)

- Enough 12mm plywood for triangle sides and stand swivel (I used scrap wood)

- One 5A rocker switch

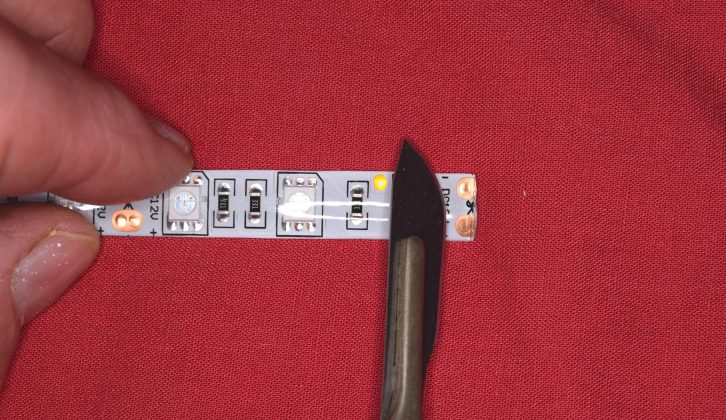

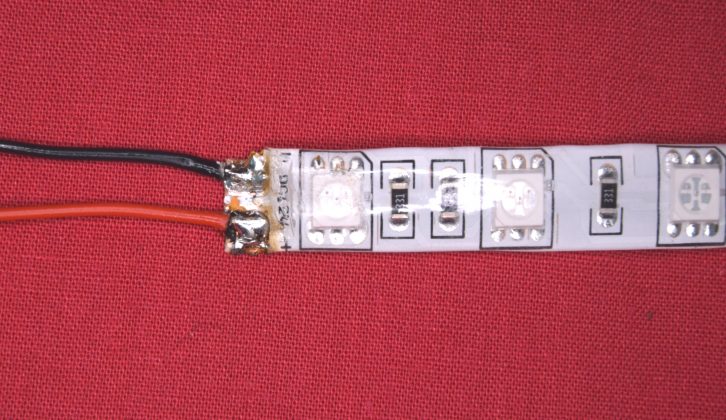

- 5m of red LED strip (Must be IP65 grade with self-adhesive backing. Only cut this at a point showing a pair of shears)

- 2m of 50mm-wide red self-adhesive reflective tape

- 0.5m of 100mm-wide yellow self-adhesive reflective tape

- Four rubber feet

- One M5 30mm bolt, one M5 self-locking nut and three M5 ‘Penny’ washers

- One 40A 12V changeover relay

- One electronic indicator ‘Flasher’ unit (bimetallic types will not work)

- Connector strip (12-way, 5A ‘chocolate block’ variety)

- Two D cell four-way battery holders

- Eight alkaline D cells

- Wire, crimp connectors, heat-shrink sleeving, wood glue, small wood screws

Tools

- Tenon saw

- Soldering iron

- Protractor or angle gauge

- Crimp tool

- Heat-shrink gun

- Drills

Time taken: around three hours

This project covers the construction of a triangle that has a large reflective red and yellow surface area and alternately flashing red LED triangles