Turbochargers are fitted to all modern diesel engines and can be expensive to repair. You can avoid trouble with these top tips

All modern diesel engines have a turbocharger. It’s basically a turbine and compressor mounted on one shaft. Some of the exhaust gas coming out of the engine is directed through the turbine, causing it to spin at high speeds. As the shaft and compressor are directly connected to the turbine, the compressor also[tl:gallery index=1 size=215×129] spins. Air coming into the engine from the air filter is directed through the compressor, compacting it to get more air into the engine.

Getting more air into an engine means more fuel can be carried in with it, resulting in improved performance – and because the air is compressed, more oxygen is getting into the engine for the same volume of air, which increases efficiency. It’s an ideal scenario: you’re given more power, but without the trade-off in fuel consumption or emissions.

Boost control

Modern turbos are controlled via the engine management computer. It adjusts the angle of the turbine nozzles to control its speed, and hence the amount of air compression. Older turbos use a valve, or wastegate, that opens and closes to control the amount of exhaust into the turbine, and thus the pressure of the compressed[tl:gallery index=2 size=215×129] air being fed to the engine.

DIY checks: what you can do

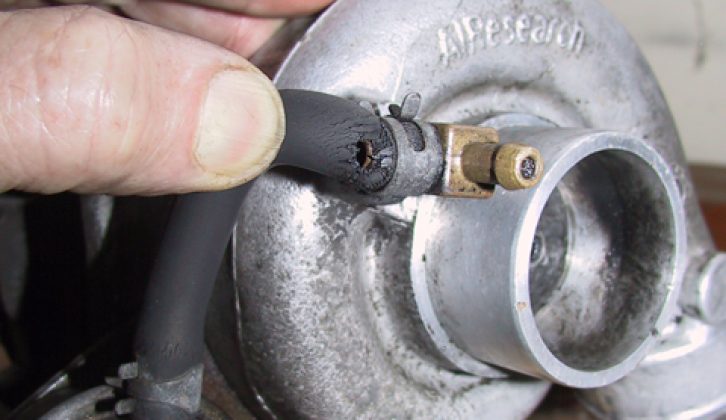

On older engines, boost pressure is controlled by an actuator, which is connected to the compressor outlet by a hose. Check the hose for splits.

Oil supply

Turbochargers rotate at over 150,000rpm on precision bearings that need a constant flow of oil, not only to lubricate them, but also to carry away the intense exhaust heat that’s transmitted along the shaft.

If the oil flow slows down, the heat can cause it to burn, producing carbon particles that score the bearings. This caused a problem on older engines when they were switched off: the heat from the turbo soaked into the oil, burning it and destroying the bearings[tl:gallery index=3 size=215×129] at the next start-up.

DIY checks: what you can do

The oil outlet pipe is connected under the turbo by a flange or union. Check here for oil leaks at the connection points.

Intercooling

For the best combustion efficiency, air entering the engine needs to be cold. However, heat from the turbocharger, as well as the fact that it’s being compressed, increases the temperature of the air, so before it enters the engine it is directed through an intercooler. The intercooler works in a similar way to the radiator: hot engine air is fed through it while outside air blowing across cools it down. This cooled air is then piped into the engine.

Small amounts of lubricating oil from the turbo bearings can be carried into the intercooler where it eventually builds up. That’s why servicing schedules suggest periodically[tl:gallery index=4 size=215×129] flushing the intercooler internally.

DIY checks: what you can do

A turbo’s intercooler is mounted at the front, usually alongside the radiator. Check for corrosion of fins and blockages, such as leaves.

Pipework

Metal pipes and flexible hoses transfer engine air from the air filter to the turbo. The air then goes through the intercooler before going into the engine. Any leaks in the pipework between the air filter and the turbo will allow dust to be drawn in, which erodes the turbo’s compressor blades. Leaks in the pipework between the turbo and the intercooler, and from there to the engine, will allow air[tl:gallery index=5 size=215×129] to escape and will lead to a loss of power.

DIY checks: what you can do

Failing to flush the intercooler can lead to sooty blockages in the inlet pipes to the engine. These need to be checked on high-mileage engines.

Caring for the system

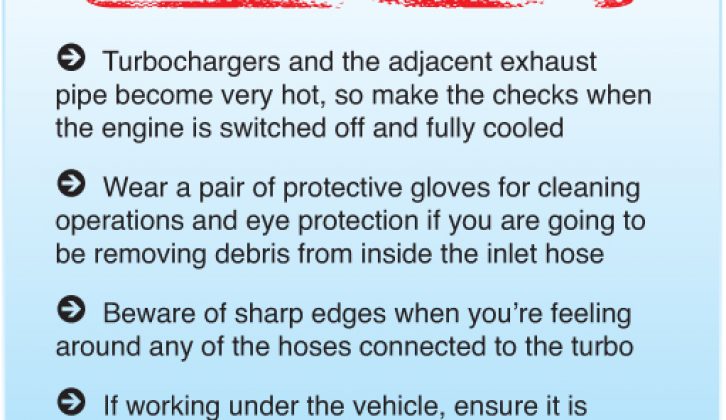

Turbo problems are difficult to diagnose and many turbos have been replaced unnecessarily. Symptoms include a high-pitched noise or whistling, exhaust smoke and power loss. However, many other engine problems can produce similar effects.[tl:gallery index=6 size=215×129]

If the engine has been run hard – such as after a long steep climb or heavy towing – don’t switch off the engine immediately. Instead, leave the engine idling while you take off your seat belt. This gives the turbo a few seconds running at zero load while the oil flushes the heat away.

Avoid using full power for the first few minutes of driving, too. This gives the turbo, and other engine components, time to heat up evenly and gradually, minimizing thermal and mechanical stress.

Servicing

Regular engine oil and filter changes are essential because the turbocharger is lubricated by the engine oil. Old oil, apart from giving reduced lubrication, will be thicker so it flows more slowly through the turbo’s bearings, removing less heat.

Ensure the intercooler is flushed at the specified interval. Otherwise, oil may be carried into the engine, affecting the valves and causing exhaust smoke.

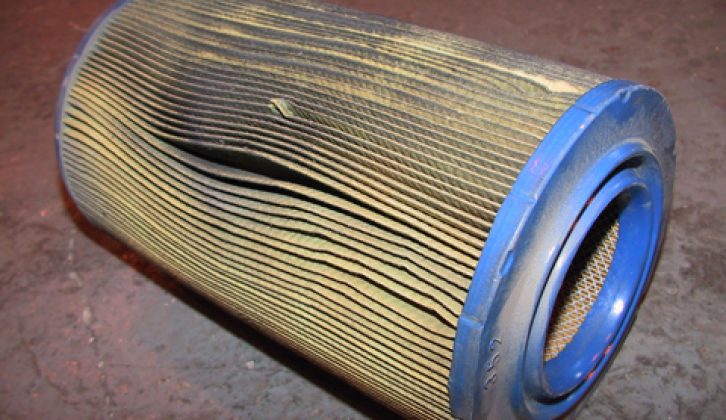

Renew the air filter at the correct intervals. When an old filter becomes partially blocked it causes a fall in engine efficiency and increases the likelihood of unfiltered air being drawn in through leaky pipework and connections.[tl:gallery index=7 size=215×129]

DIY checks: what you can do

Air filters should be changed at the prescribed service intervals, or sooner if the vehicle has been driven in dry, dusty conditions

More DIY checks

There is normally no need to remove air hoses; however, you should still give them a squeeze to expose splits and perforations, [tl:gallery index=8 size=215×129]and confirm the ends are sealed tight and that fixing clips are secure. Look for kinked hoses that will restrict the air flow and reposition hoses that are rubbing against metal parts.

Use a torch to inspect the oil pipes at the turbo. There’ll be a supply from the engine, usually into the top of the turbo, and a drain pipe or hose underneath leading into the sump or engine block. Look for oil leaks here and around the flange gaskets and hose connections.

On older engines, it’s worth disconnecting the air inlet hose at the engine’s manifold and having a look inside the hose and manifold. Oil and carbon can collect there.

[tl:gallery index=9 size=459]